There’s nothing more frustrating than your cable failing to deliver a signal when you need it most. Whether you’re using a coax cable for audio/video transmission or internet, coaxial cable testing can help you uncover the problem and fix it fast.

You’ll learn how to test a coaxial cable for signal integrity below. A multimeter is typically the best approach for testing coaxial cable issues, but there are other solutions we’ll share as well - like signal meters, TDRs, and even just looking for interference.

Most importantly, though, we’ll help you figure out what to do if you discover after testing your cables that a replacement is in order. You can get back up and running fast with the #1 bulk coaxial cable selection online here at AudioVideoElectric.com.

Overview of Coaxial Cables

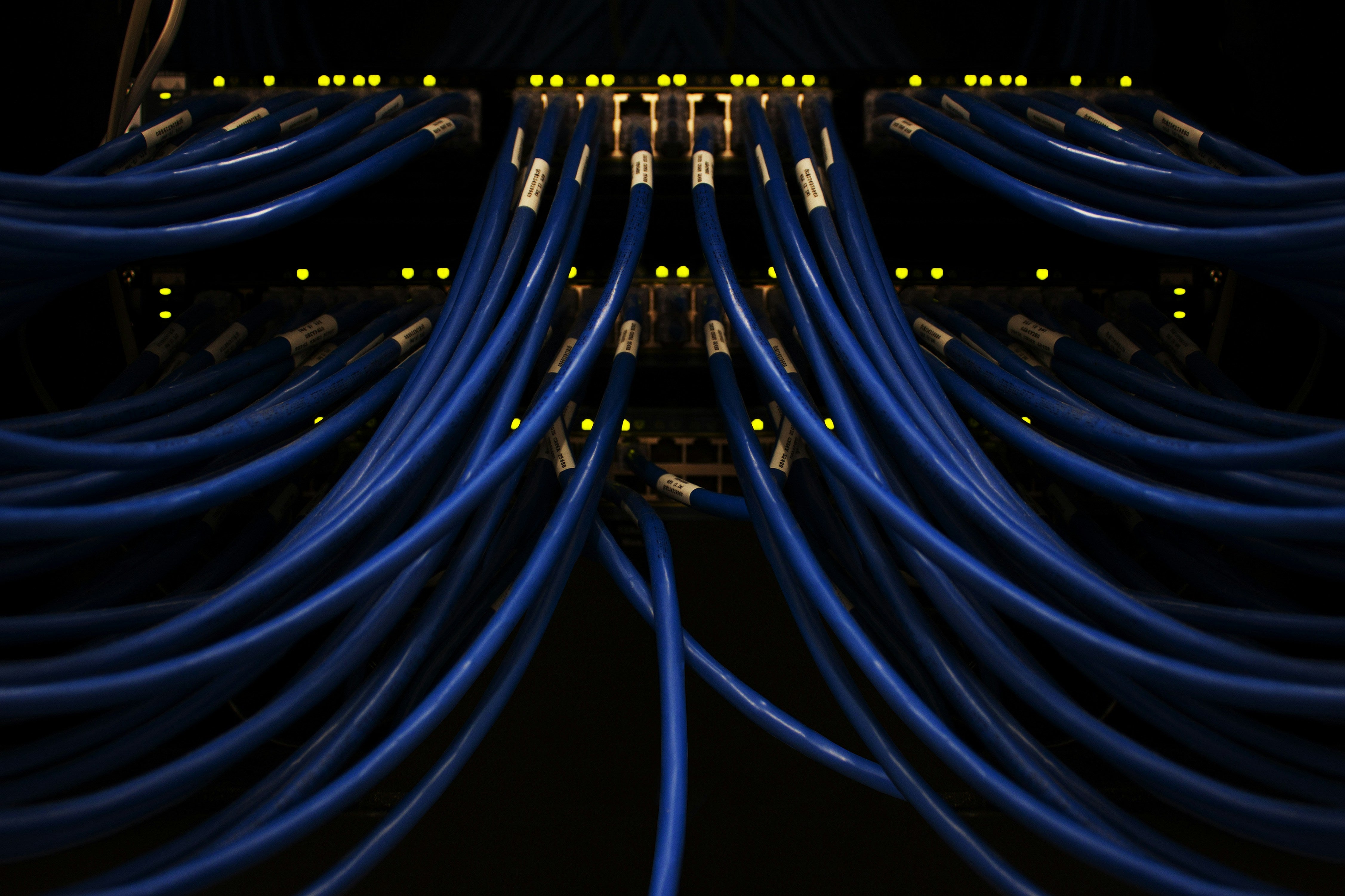

Coaxial cables are used to transmit high-frequency signals with minimal interference and signal loss. They feature four main components: an inner conductor, a dielectric insulator, a metallic shield, and an outer jacket.

The inner conductor tends to be made of copper or aluminum and is what actually carries the signal. It’s surrounded by the dielectric insulator which maintains a consistent distance between it and the metallic shield - the component responsible for protecting against electromagnetic interference (EMI). The outer jacket provides physical protection.

Each component plays a part in the reliability and efficiency these cables are known for. They’re widely used for television and radio broadcasting, internet and broadband connections, CCTV and surveillance systems, and military and aerospace communications.

But like all electrical cables, they’re subject to failure as a result of age, improper connections, incompatibility, and other issues. That’s why you need to know how to test a coaxial cable.

How to Test a Coaxial Cable for Signal Integrity

The concept of coaxial cable testing can be stressful. But it’s actually fairly simple and straightforward, especially when you have a multimeter on hand. We’ll show you how to use one of these testing devices below along with a few other ways you can go about testing coaxial cables.

Testing a Coaxial Cable With a Multimeter

A multimeter is a tool for measuring voltage, current, and resistance. It’s the easiest and most accurate way to test the continuity of a coaxial cable. Here’s how to do it:

- Gather your tools. You’ll need a multimeter, a coaxial cable stripper, and the cable to be tested.

- Inspect the cable for visible damage, such as cuts or kinks.

- Turn the multimeter on and set it to the continuity or resistance (ohms) setting.

- Touch one probe to the center conductor at one end of the cable and the other probe to the center conductor at the other end.

- A reading close to zero indicates good continuity; a high reading or infinity indicates a break in the conductor.

- Repeat the process for the outer shield, ensuring it also has good continuity.

Now, if you want to check your cable for shorts instead of continuity, there is a slightly different protocol. You’ll simply touch one probe to the center conductor and the other to the outer shield. The multimeter should show no continuity (infinity); if it shows continuity, there is a short in the cable

Signal Strength Test With a Signal Meter

You could also consider testing signal strength of your cable using a signal meter. Here’s how:

- Gather a signal meter, coaxial connectors, and the cable.

- Attach the cable to the signal meter for a secure connection.

- Turn on the signal meter and read the signal strength.

- Compare the reading to the expected signal strength for your application. A big drop in signal strength may indicate issues with the cable.

If the signal strength is below expectations, inspect the cable for damage or poor connections. Repeat the test after addressing any issues and see if you were able to fix the problem.

Using a Time Domain Reflectometer (TDR)

A Time Domain Reflectometer (TDR) is a more sophisticated tool used to detect faults within a cable. It works by sending a signal down the cable and measuring the reflections. Here’s how you’d go about coaxial cable testing with a TDR:

- Gather a TDR, coaxial connectors, and the cable.

- Connect the cable to the TDR and power it on.

- The TDR will send a signal through the cable and display a trace on the screen.

- Analyze the trace for reflections, which indicate faults such as breaks, shorts, or impedance mismatches.

The distance to the fault can be determined by the position of the reflection on the trace. Address any identified issues and retest to confirm the cable is functioning correctly. If not, it may be time for a replacement.

Checking for Interference

There’s one more thing we want to show you for how to test a coaxial cable - looking for EMI to detect interference. After all, interference can degrade the performance of your cable. Here’s how it works:

- Gather an EMI meter and the coaxial cable.

- Turn on the EMI meter and scan the area around the cable.

- Identify and document sources of interference.

Pretty simple, right? Then it’s just a matter of addressing the interference in question. Shield the cable or relocate it away from interference sources. Then, repeat the scan to ensure the interference has been mitigated.

What if After Testing Coaxial Cable You Find Out It’s Not Working?

Now that you know how to test a coaxial cable it’s time to start looking for solutions. There are two ways this can go - you can address the root cause of the problem or replace the cable altogether. We’ll unpack both options below.

Unpacking Common Coaxial Cable Problems

Coaxial cable testing is just the first step. Once you determine the cable isn’t working, you must identify the root cause and determine the appropriate solution. Here are some common issues and their diagnostics:

- Physical Damage: Cuts, kinks, or abrasions on the cable jacket can disrupt signal transmission. Examine the cable thoroughly for any visible signs of damage and replace the cable if necessary.

- Poor Connections: Faulty or improperly installed connectors can lead to signal loss or interruption. Ensure that all connectors are securely attached and free from corrosion.

- Signal Interference: EMI from nearby electronic devices can degrade signal quality. You should move interfering devices away from the coaxial cable or install EMI filters to block interference. Or, upgrade to better-shielded cables.

- Internal Faults: Breaks or shorts within the cable can significantly impact performance. So, locate the exact point of failure and determine if a fix is possible - otherwise, you’ll need to replace the cable.

- Aging and Wear: All types of cables can deteriorate over time, leading to reduced performance. If the cable is old, consider replacing it as a preventive measure.

Finding a Reliable Replacement at AudioVideoElectric.com

A lot of the times the only solution for addressing cable-related problems is to find a suitable replacement. This can be frustrating, complex, and expensive. But it doesn’t have to be. AudioVideoElectric.com is proud to present our selection of Belden alternative cables.

These offer the same high performance as brand-name cables at a fraction of the cost. They’re identical in fit, form, and function, making for an economical solution without compromising quality.

In fact, we’ve had customers save up to $86,000 annually by making the switch to our cables, while other customers have trimmed 65% of their cable budget without any sacrifice in reliability, efficiency, or longevity.

Whether you need RG-6, RG-11, RG-59, or specialized triaxial cables, our catalog has what you need. You can even find the best selection of multi conductor cables here, too!

We have spec sheets on hand to help you soure the right replacement. Our dedicated support team is available to help you choose the optimal cable for your specific application as well. So, get in touch today or browse our catalog as we wrap up our guide on how to test coaxial cable.

Wrapping Up Our Coaxial Cable Testing Guide

Regularly testing coaxial cables helps you uncover issues before they spiral into bigger problems. Coaxial cable testing is also essential for pinpointing specific failures and planning out your next steps.

We hope this guide on how to test coaxial cables has left you with a clear understanding of your next steps - be it sourcing a multimeter or a TDR, an EMI meter, or anything else.

Remember that you don’t have to navigate this process alone either, our customer service team is available to help you troubleshoot and replace your cables with confidence.

So, what are you waiting for? Invest in top-tier performance without busting your budget. Find the perfect coax cable for your unique needs at AudioVideoElectric.com today.